In-situ biological reduction (ISBR) with bioaugmentation, Greven

- 01 to 05/24 Cultivation of microorganisms

- 06/24 Bioaugmentation and second input campaign

Successful bacterial growth and pollutant degradation

At the site of a former electroplating and hardware factory in Greven, significant contamination of the soil, soil air and groundwater by volatile chlorinated hydrocarbons (VCHCs) was detected. In order to optimize the progress of the remediation, measures for in-situ biological reduction (ISBR) were successfully tested, planned and commissioned for implementation.

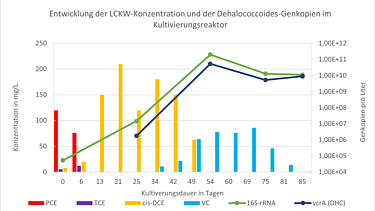

At the beginning of 2024, ZÜBLIN Umwelttechnik cultivated a total of 800 liters of concentrated bacterial stock solution of the CHC-degrading species Dehalococcoides mccartyi in a closed fermentation reactor under strictly controlled, anaerobic conditions. The controlled addition of special MolaZUT® formulations, neutralizing agents and tetrachloroethene as a degradation component intensified the development of the bacterial cultures. Analytically, a reductive dechlorination of the added CHCs was observed, in which tetrachloroethene was gradually degraded to ethene, with a simultaneous increase in bacterial density up to 10^11 gene copies per liter.

The cultures were introduced during the second infiltration campaign in June 2024 by displacing the atmospheric oxygen in the wells and pipes in advance with a nitrogen-carbon dioxide mixture.

Bioaugmentation in conjunction with biostimulation and the introduction of auxiliary substrates makes it possible to create a very high reductive degradation potential in the groundwater. This method is particularly suitable for remediation sites where there is insufficient degradation behavior under natural conditions due to a lack of or unsuitable bacterial cultures.

Special features

- Cultivation of 800 liters of bacterial stock solution

- Results of the qPCR analysis:

- 2.0 x 1011 16S-rRNA gene copies/L stock solution

- 5.3 x109 vcrA (DHC) gene copies/L stock solution

Scope of services

- In-situ biological reduction by substrate input (molasses, pre-fermented, MolaZUT®), bioaugmentation (input of cultivated bacteria Dehalococcoides mccartyi)