In-situ thermal remediation, Bellinzona (Switzerland)

- Floor air extraction with 1,100 m³/h, negative pressure up to 300 mbar

- Groundwater purification system up to 25 m³/h

- Installed heating capacity 730 kW, 350 kW cooling capacity

- Removal of approx. 210 kg of pollutants (corresponds to approx. 95 % of the inventory)

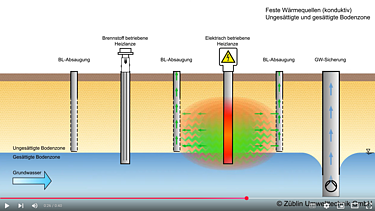

Thermal remediation of an CHC leak

The site of a former dry cleaning facility was heated using fixed, electrically operated heat sources (Video clip) and soil vapor extraction. The subsoil has a very inhomogeneous structure and low permeability. The LCHCs were located in the unsaturated soil zone at a depth of up to 15 m below ground level. The heating of the soil body and the extraction of the CHCs took place over an area of approx. 1,000 m². The outflow was hydraulically secured with the help of a groundwater purification system.

The remediation has been successfully completed and the remediation objectives have been achieved.

Scope of services

- ISTH refurbishment: 194 drill holes for

- 60 electric heating elements

- 56 pcs. soil vapor extraction level

- 77 temperature lances

- Soil air purification: Air activated carbon filter

- Groundwater purification plant

- Sand filter, activated carbon water filter

- Telecontrol technology, process visualization

- Supply and operation of heating and measurement technology

- Delivery and operation of the two-stage soil vapor extraction system and soil vapor purification via activated carbon air filters