PFAS soil-washing and water purification systems

PFAS soil-washing

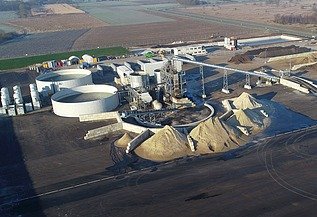

ZÜBLIN Umwelttechnik has many years of experience with soil washing, especially with PFAS (perfluorinated and polyfluorinated alkyl substances), which are known as perpetual chemicals. Plant technology and operating processes have been continuously improved, enabling us to further expand our position as market leader in this technology in Germany. The current volume of 800,000 tons of soil successfully cleaned up speaks for itself. These soils have been decontaminated to such an extent that they can be reused as backfill material.

We will be happy to examine your specific case of damage and offer you tailor-made solutions depending on the size of the project (10,000 m³ to >>100,000 m³), the level of contamination and the nature of the soil. We can draw on a wide range of equipment sizes and types from our rental equipment pool at short notice and guarantee rapid and cost-effective processing.

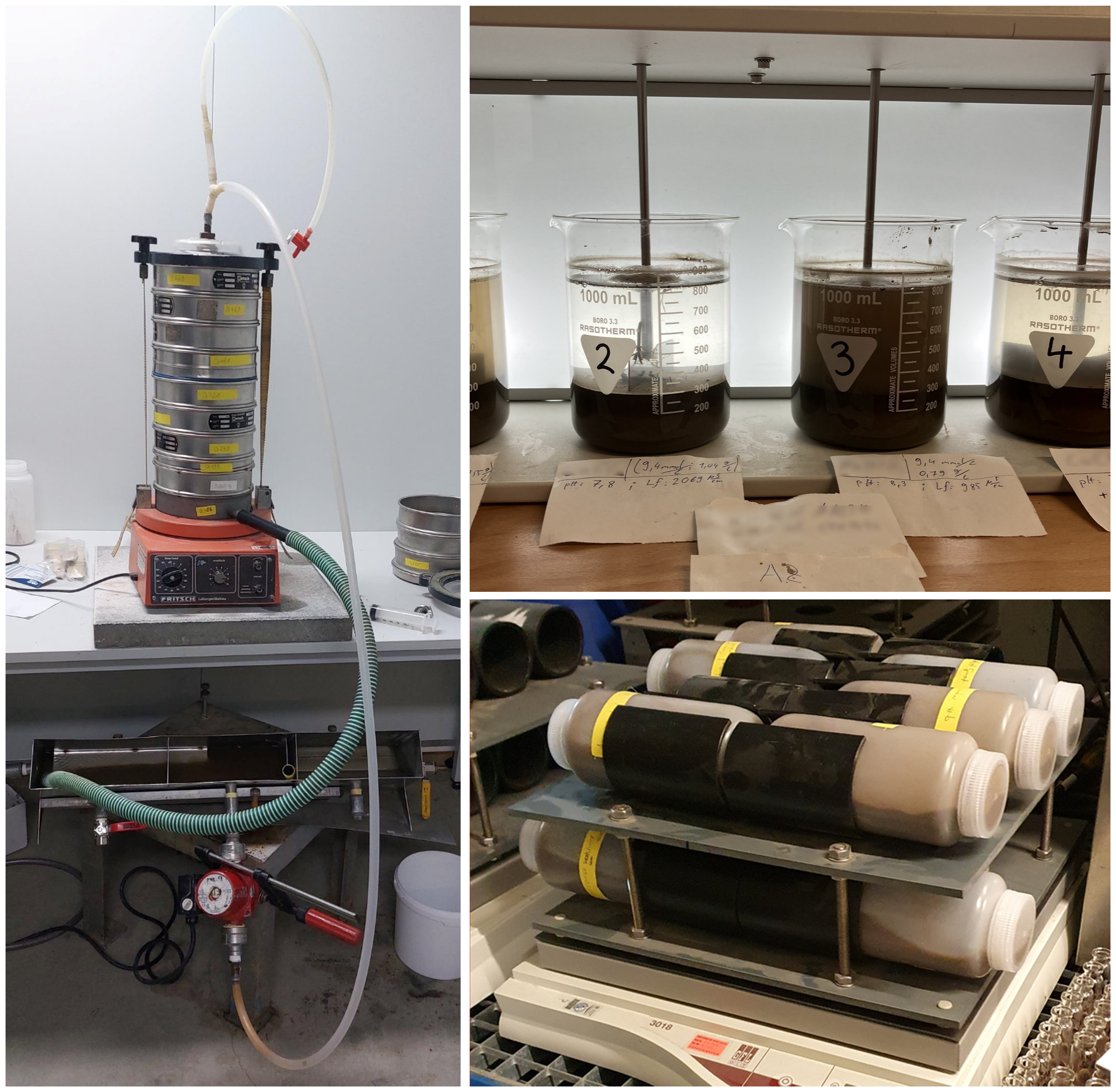

Insight into the technology of PFAS soil-washing

On the one hand, the contaminated soil is classified in order to be able to process the different fractions with specific aggregates. On the other hand, intensive contact between the washing water and the contaminated soil is created in the process of wet mechanical separation so that the PFAS are transferred from the grain to the wash water.

The contaminated wash water with fines is treated in the sludge treatment plant with optimized use of chemicals for precipitation/flocculation. The thick sludge is dewatered using a chamber filter press. The separated clear phase is transferred to a further purification plant.

Large buffer tanks offer high operational reliability and enable resource-efficient operation of the wash water treatment plant with recirculation of the wash water.

Several filter stages are used in the multi-line wash water purification plant. The activated carbons used are optimally adapted for efficient use in the overall project (PFAS optima ®).

Insight into the

Solutions for contaminated water: specialized purification systems

ZÜBLIN Umwelttechnik has extensive experience in the purification of PFAS-contaminated media and has designed and built over 50 individual purification systems for various locations throughout Germany and Europe since 2009.

The PFAS purification processes for aqueous media such as groundwater, seepage water, fire extinguishing water, process water or water for irrigating agricultural crops are similar in principle. However, depending on the water quality and purification objective, additional treatment steps are required.

The activated carbon adsorption, ion exchange, flocculation and membrane processes are currently considered state of the art. Recent developments show that foam fractionation is a promising method for removing high PFAS concentrations. Adsorption on activated carbon is generally the most efficient and cost-effective method for the purification of PFAS-contaminated aqueous media.

Our highly activated, agglomerated grain activated carbon PFAS optima® is particularly suitable for the removal of PFAS compounds. This allows contents of < 1 ng/L (!) per individual substance to be achieved, even for short-chain PFAS, as our experience has shown. PFAS-laden activated carbon can be reactivated in special high-temperature furnaces with exhaust gas post-combustion and alkaline washing. The reactivate is reused so that no waste is produced for disposal.

Get in touch with us!

Whether soil contamination, sprinkler water, groundwater or rinsing water - we have the right solution.

to the contact finder